CNC Machining Applications | Precision Linear Guides and Ball Screws

Learn how high-precision linear guides and ball screws enable accuracy, rigidity, and repeatability in CNC machine tools.

Explore how Motiontek’s linear guides, ball screws, and linear modules enable precision and reliability across automation, robotics, semiconductor, and medical industries.

Motiontek supplies precision linear guides, ball screws, and linear modules that power motion-critical equipment across multiple industries. From CNC machining cells and robotic assembly lines to cleanroom semiconductor tools and medical analyzers, our components deliver the smooth, repeatable movement that modern automation demands. Each product family is engineered for micron-level accuracy, high rigidity, and long service life, and is supported by application engineers who help you select rails/blocks, screw leads, preloads, coatings, and module configurations that match your duty cycle and environmental constraints.

The real value of a motion system is measured in uptime and yield. That’s why we focus on the details that determine reliability in the field: precision grinding of raceways, matched rail–block sets in sizes 15–65 mm, optimized preload classes for stiffness without excess friction, and surface treatments that resist corrosion and particle generation. Our linear guideways and ball screw drives integrate seamlessly with modular stages to shorten design-to-production lead time. Whether you are building new equipment or retrofitting legacy machines, Motiontek provides clear specifications, traceable QC, and consistent delivery—capabilities that OEMs and system integrators rely on when scaling production.

Browse the applications below to see how Motiontek’s linear motion components are applied in real machines. Each page outlines common axis layouts, recommended guide/screw specs, environmental notes (lubrication, dust, temperature), and integration tips that help you hit target accuracy with minimal iteration. If you need a non-standard stroke, preload, lubrication scheme, or coating, our engineering team can tailor a solution and provide drawings, life calculations, and sample lead times. Motiontek is your partner for dependable linear motion—from prototype to mass production.

Learn how high-precision linear guides and ball screws enable accuracy, rigidity, and repeatability in CNC machine tools.

Explore how linear guides, ball screws, and linear modules enable high-precision motion in semiconductor manufacturing and cleanroom automation.

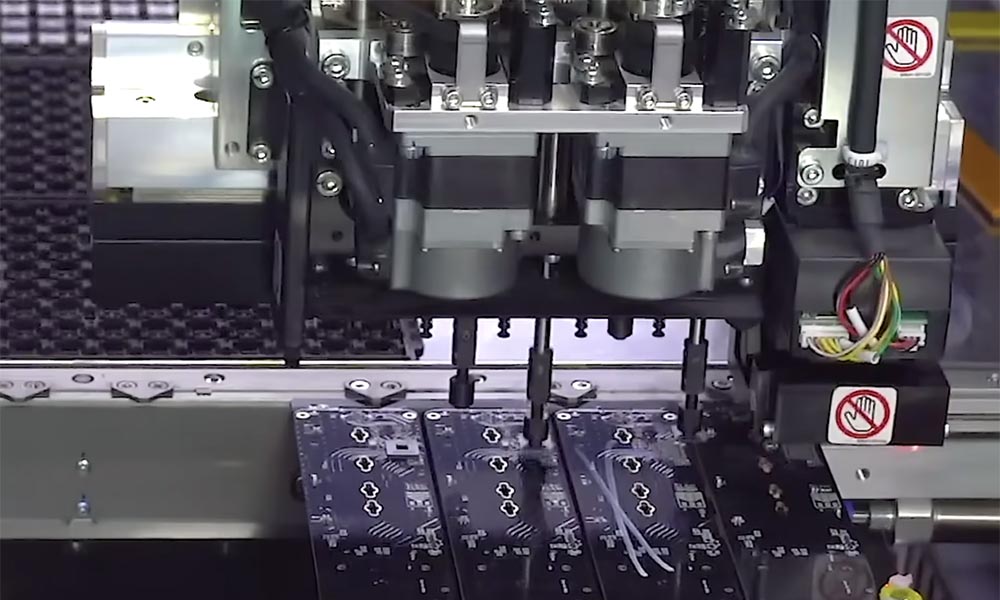

High-performance linear guides, ball screws, and linear modules designed for electronics assembly equipment and SMT automation.

Discover how Motiontek linear guides, ball screws, and linear modules enable high-precision 3D printing and additive manufacturing systems.

Precision linear guides, ball screws, and linear modules for medical devices, diagnostic imaging, and laboratory automation systems.

Explore how linear guides, ball screws, and linear modules enhance precision, reliability, and efficiency in modern industrial automation systems.

Tell us about your project and required specifications. We supply linear guides, ball screws, and linear modules with reliable lead time and technical support.